Product Center

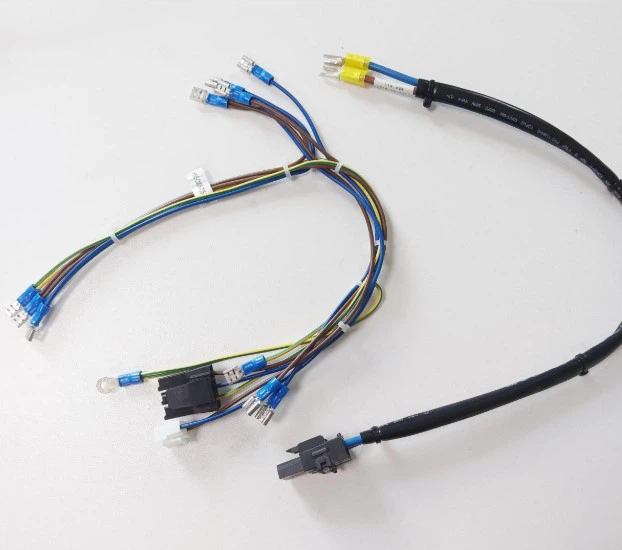

In kitchen appliances and smart appliances, due to the limitation of usage space, Custom Wire Harness can be designed to be lightweight and compact.

In industrial high-intensity applications, the use of Teflon or silicone cables can prevent machines from overheating and enhance the durability of the wire harness.

In the fields of consumer electronics and game consoles, wire harness shielding layouts are adopted to prevent interference with signal transmission and screen flickering.

In network connections, the wire harness component is equipped with a hot-swappable function, enabling quick replacement and maintenance of faulty components and reducing failure losses.

In the telecommunications field, high-quality copper cable assemblies are configured, and the shielding layer can prevent electromagnetic interference, ensuring unobstructed signal transmission.

In the layout of automotive Wiring harnesses, the replacement of wire materials, optimization of layout, and shortening of length are achieved by using the Wiring Harness Diagram to realize lightweight design.

In CT machines and X-ray equipment, to prevent electric shock during use, the wire harness is highly insulated with high-quality PTFE material.

During flight, to deal with the vibration caused by uneven air flow, the wire harness layout adopts an anti-vibration design for fixation, reducing vibration and impact force.

About ECOCABLES

Customized Solutions

Based on application-specific needs, we provide custom services to ensure our cable assemblies perfectly fit your system.

Small MOQ

Offering small MOQ, making our products available to businesses of all sizes. 50 pieces are acceptable.

Fast Delivery

3-5 working days for small quantities, and 7-15 working days for large quantities.

Reliability Assurance

With 100+ advanced testing instruments, we ensure every product meets professional standards.

Wiring Harness Cost Design Solution

Based on cases from our real clients, we have helped them reduce costs by approximately 20% through professional customization of wiring harnesses to optimize the structure.

Get Free PlansStart your customization

ECOCABLES offers you free drawing design services, optimizing the wiring harness design based on industry and application scenario requirements to maximize the value of the wiring harness.

Contact Now

01

Wire cutting

The cutting machine precisely cuts to a distance of 0.01mm, resulting in neat cuts.

02

Terminal crimp

The terminal crimping position has zero error and the edge of the indentation is smooth.

03

Peeling

Use a pneumatic wire stripper to remove wires quickly without causing any damage.

04

Tin plating

Precisely control the tin plating time to ensure that the tin layer fully covers the core wire.

05

Assembly

The terminal is inserted into the connector, and the binding wire points are firmly knotted.

06

Twist

Tighten the conductor to prevent loosening and ensure stable conductivity.

07

Inspection

Inspect the appearance for any damage and check if there is any looseness.

08

Test

Conduct conductivity and insulation tests to check if there are any issues with the circuit.

Common Questions & Answers

-

What is another name for a wiring harness?Another name for wire harness is Cable Assembly. Cable Assembly generally has a more complete protective jacket, can be plugged in and used, and comes with connectors.

-

What are the three types of wiring harnesses?Three types of wire harnesses:

1.Integrated Cable Assembly: It is multi-functional and complex, integrating resistors, connectors, conduits, etc. It can be plugged in and played, which is very convenient.

2.Standard Open Harnesses: They have a simple structure and are all basic structures. The wires branch out into multiple branches in the main trunk and are bound with cable ties.

3.Molded Harness: Use a mold to wrap the wire, connector and branch into a single unit. -

What is the difference between wire cable and harness?Overall, wire and cable are materials, while harness is a finished product made from these materials. wire and cable are simple wires that cannot bring out greater value. However, a wire harness is a targeted solution made from wires that can address the problem of chaotic wire harnesses among devices in different industries.

-

How is the role of wire harness system in vehicle?The wire harness system plays a role in transmitting signals, electricity and control instructions in vehicles. Specifically as follows:

1. Signal and data transmission: Instructions such as throttle, vehicle speed, and temperature are transmitted through the wiring harness system.

2. Power transmission: Transmit the power from the battery to other components that require electricity.

3. Ensuring safe driving: As a circuit protection system, fuses need to have the characteristics of being waterproof and heat-resistant. Through the reasonable layout of the wiring harness system, protection can be achieved.

4. Integrated vehicle functions: Individual electronic components can be integrated into a stable system. -

How to reduce the cost of wire harness design?Reducing the cost of wiring harnesses can be approached from the following aspects:

1. Choose materials with excellent cost performance. On the basis that the wiring harness can achieve the same performance, give priority to choosing more cost-effective materials to save material costs and avoid material waste.

2. Design the structure based on actual applications. If in practical use, there is no need for complex structural design at all, then designing the structure according to the actual application and simplifying it will save a considerable amount of money.

3. Simplify the components that do not affect the function of the wiring harness. In the overall wiring harness, even if a certain component is removed, it still does not affect usage. Therefore, eliminating redundant components is a breakthrough point for reducing costs.

-

+

Factory land occupation

-

+

Senior technical engineer

-

+

Utility model patent

-

+

Global customers